The easy storage of some food materials such as fruits and vegetables is propagated by the use of baskets. Baskets have found their usage in virtually every industry for storage and /or transportation.

However, most people are much more familiar with the more relatable woven basket. Even at that, the plastic-made baskets which are made from injection molding are more frequently utilized.

Most people, especially adults have a clear idea about how the conventional basket is made. However, it's been a myth to most people especially those that are unskilled in that aspect.

It is no doubt that you must have someway imagined how these baskets you see all around are being made. The principle of its manufacture is based on injection molding in which the melt material is preheated and forced into the configuration of the mold at a good speed.

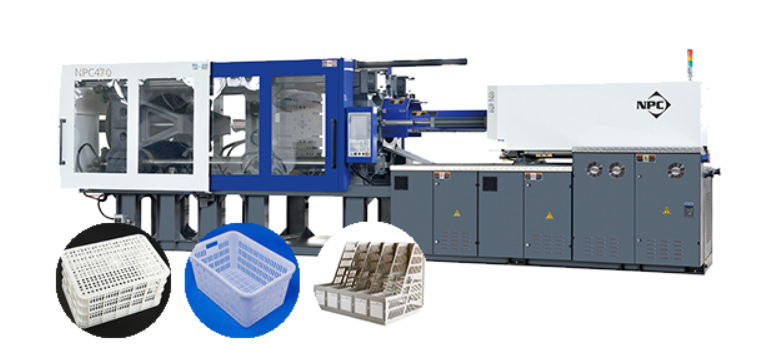

The need for more quantity and ensuring better delivery while still maintaining the appropriate quality led to the development of the basket injection molding machine.

Do you still need more necessary information about the benefits of using a machine rather than the conventional method?

This article gives you detailed insights into the benefits of using a basket injection molding machine.

Quite certain that the first thing that comes to your mind when you see this benefit is the question, "what does this mean?"

This simply means that after preheating the amount of melt material that can be used to fill their mold in the machine is large. Simply put, since the amount of input is large, the resulting output, under proper machine functioning conditions will also be expectedly large. This in turn results in improved productivity while still giving quality products.

The speed of a machine is very important as it is a key determinant in establishing how productive such a machine is.

The basket injection molding machine has a high speed which is attributed to its revolution per minute. Its high-speed results in an increase in output per unit time.

There is a possibility of variations in the materials used for manufacture including the color. At this point, it is important to carefully decide the appropriate material combination that should be used.

Similarly, you can have distinct colors in your basket. The resulting color is visible due to the addition of the corresponding raw color in the material combination.

Machines have been confirmed to give reasonably high efficiency. The amount of input is relatively close to that of the output. Also, by making use of a basket injection molding machine, you can be sure of a continuous work process that does not require expertise.

You can inarguably attest to the increased production capacity in industries as a result of the use of machines. This ultimately increases the profit.

Should you decide to purchase yours now, you can easily reach out to us to take advantage of this offer.

Contact us today to get your best performance basket injection molding machine at cost-effective prices