Better Price

Become Our Agent To Get Competitive Price In Your Local Market And Get More Profit

We specialized in the customized turnkey solutions for different plastic products. Until now we had highly experience in containers IML(in-mold-labeling)&stack-over project, custom-design products take out from the mold, cutlery project and other brand-new design. All are design for the purpose labor cost saving , higher production capacity, energy saving.

NPC Always Looking For A Agent Who Can Provide Better Pre-sales And After-sales Service For Our Customers In Local Market.

If You Are An Agent And Looking For A Good Supplier of Plastic Injection Molding Machine. Please Fill Out The Form Below To Get More Cooperation Details.

Become Our Agent To Get Competitive Price In Your Local Market And Get More Profit

24 Hours Online Service And Overseas Installation & Maintenance

Deploying Local Online Advertisement For Product Promotion And Brand Influence

Visiting Our Factory And Support Training For Setup, Processing & Troubleshooting

NPC with an experienced R&D team provide various custom-design turnkey solutions to make your complete project—Energy saving, labor cost saving, less material wasting.

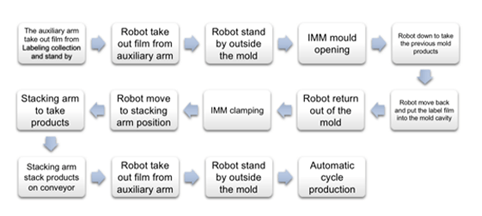

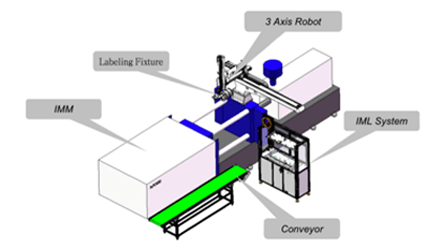

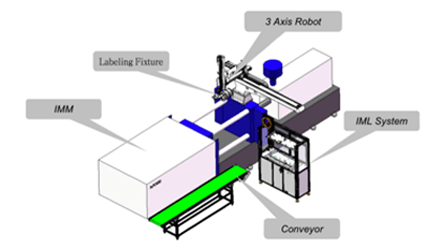

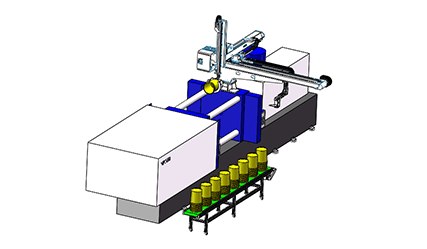

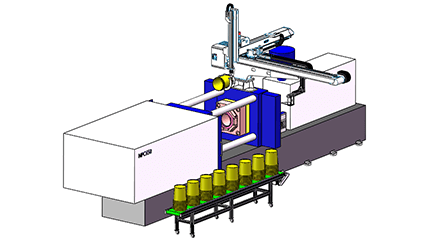

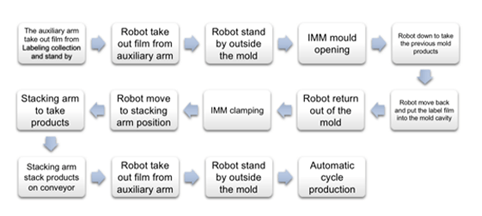

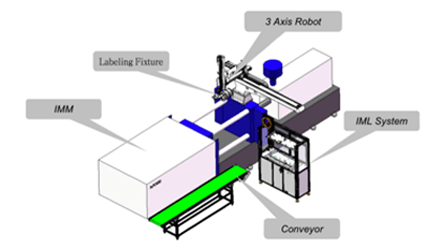

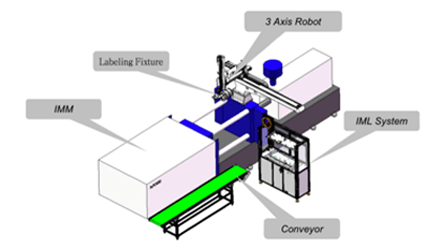

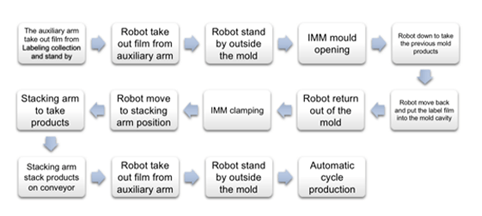

Fully automatic labeling and take-out the product, the complete movement operate by a single robot. Compare with the traditional technology, it can save at least 2 labor’s cost, space saving and speed up the production capacity.

The complete system work with a customized PLC program and individual label working platform, combine with up-to-date top-entry system achieve the purpose of cost control and keep the high production capacity. 1 single system including the function of take out, label putting, labelling, and stack-over.

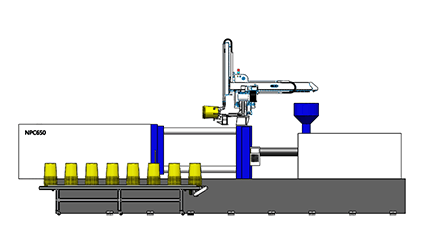

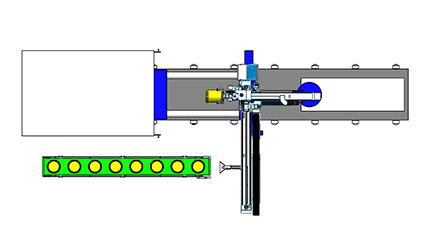

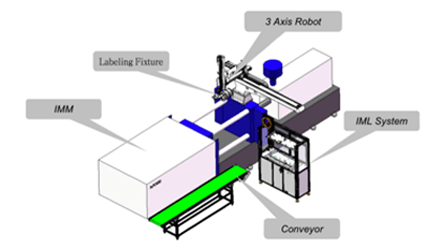

Top-entry style in-mold-labelling way: 3 Axis Robot connected with the injection molding machine combo as a complete system, this design to avoid always-adjusted before machine start, with precise positioning and less aftersales problem.

Labelling fixture is formed by 3D printing technology, the air tube well organized with internal design inf the fixture, the overall structure is lighter and easier to operate.

We have an intimate knowledge of various kinds of injection molding machines’ structure and with rich experiences in custom design stack-over project, our solutions fully considered labor cost saving, improvement on the production capacity, energy saving. With entry level and high speed level as options.

Customized automatic stacking machine according to customer’s production needs, base on the production dimension, stack-over request to achieve automatic product take-out, positioning adjust, and stack-over to the request position. The complete system space saving and compact design.

The whole process doesn’t require manual intervention except for manually picking and placing the stack the products from the loading and unloading machine. The simple operation achieve one-person-operate, less the complete labor cost and improve the production capacity.

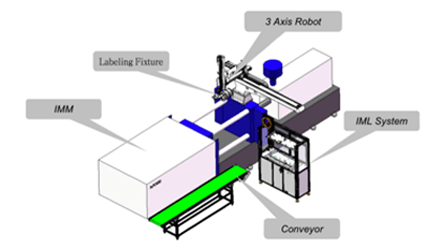

Fully automatic labeling and take-out the product, the complete movement operate by a single robot. Compare with the traditional technology, it can save at least 2 labor’s cost, space saving and speed up the production capacity.

The complete system work with a customized PLC program and individual label working platform, combine with up-to-date top-entry system achieve the purpose of cost control and keep the high production capacity. 1 single system including the function of take out, label putting, labelling, and stack-over.

Top-entry style in-mold-labelling way: 3 Axis Robot connected with the injection molding machine combo as a complete system, this design to avoid always-adjusted before machine start, with precise positioning and less aftersales problem.

Labelling fixture is formed by 3D printing technology, the air tube well organized with internal design inf the fixture, the overall structure is lighter and easier to operate.

We provide other machines’ one-stop purchase service

Automatic labeling system

Automatic & Semi-automatic blow mold machine

Various types of packing machine

Extrusion machine

Rubber machine

Vertical injection molding machine

Spare parts of other brand’s injection molding machine

If you are interested in our products, please contact us

contact usBy continuing to use the site you agree to our privacy policy Terms and Conditions.