An electric motor is a type of electromechanical energy converter, that converts electrical energy into mechanical energy in the form of shaft rotation.

Electric motors are classified into many types based on their electric supply and operation, which is DC motors, induction motors, stepper motors, servo motors, and many more.

Discover the key difference between a servo motor and a DC motor by reading this article. However, let's first go through the fundamentals of servo motors and DC motors before talking about their differences.

A servo motor is a kind of electric motor that acts as a rotary actuator and permits exact control of angular velocity, position, and acceleration.

A servo motor has a sensor for position feedback on its rotor to continuously regulate its position and speed. The closed-loop control system design of servo motors serves as a general description of these devices.

The two different types of servo motors are AC and DC servo motors. Whereas DC servo motors are utilized in small electronic devices like robotic joints, camera focusing systems, antenna positioning systems, CNC machines, etc., AC servo motors are employed in huge applications.

A DC motor is a type of electric motor that, as its name implies, transforms electrical energy in the form of direct current (DC) into mechanical energy (rotation of shaft).

There are two different forms of DC motor construction: brushed DC motors and brushless DC motors. However, when we refer to a DC motor as a whole, we are merely referring to brushed DC motors.

A DC motor is made up of a stator component that creates the magnetic field system and a rotor component that serves as the motor's armature. On the rotor's shaft, a commutator is additionally placed. The ends of the armature winding are joined to the commutator segment.

The Servo motor comprises three major wires which are power, control, and ground, in the DC motor, only works with two wires which are power and control.

A servo motor is assembled from four main components: an appropriate motor, gearing set, position sensor (encoder), and control circuit. In the case of a DC motor, there is only one DC machine and no further parts.

Servo motors injectors operate at high speeds, often between 1000 and 6000 RPM. Depending on the motor type, DC motors can run at a modest speed.

Servo motors injectors have intricate control systems. They can be effectively controlled, though. DC motors have a basic control system. To change the direction of rotation, we only need to reverse the leads, and to alter the speed, we simply need to adjust the voltage.

Servo motors are widely utilized in positioning systems, robotic joints, camera autofocus systems, and industrial automation. Mechanical loads are driven by DC motors. Cranes, elevators, lifts, toys, kitchen appliances, etc. all frequently use these.

The efficiency of the servo motors is high compared with the DC motors which are average and the cost of purchasing servo motors is quite expensive compared to Dc motors which is less expensive.

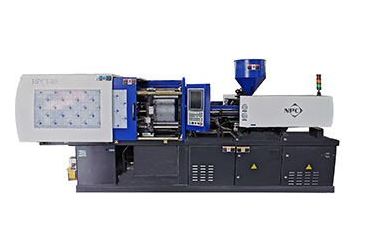

You can trust us as a leading brand with a strong dedication to quality when it comes to high-grade servo motor injectors and other types of motor injectors.

Therefore, please click to contact us for our products if you need any of our products or services. We will be happy to work with you.

By continuing to use the site you agree to our privacy policy Terms and Conditions.