With the wide application of high-speed injection molding machines, it has increasingly become one of the injection molding machines that manufacturers pay attention to. However, what is the difference between a high-speed injection molding machine and an ordinary injection molding machine? It became a hot topic of discussion. Let us introduce the difference between high-speed injection molding machine and ordinary injection molding machine.

Generally speaking, high-speed injection molding machines are all electric motors, while ordinary injection molding machines are hydraulic injection molding machines, and hydraulic injection molding machines operate relatively slowly. The servo motor used in the all-electric high-speed injection molding machine realizes the opening and closing of the mold, ejection and demoulding, raw material injection and storage, etc. The running speed is fast and precise, which greatly improves the production environment and production efficiency. But now the servo electric injection molding machine only has a clamping force below 850 tons.

To sum up, the high-speed injection molding machine adopts a hybrid type of oil pump and servo motor. The advantages of the servo hydraulic system are: the soft start mold will not affect the power network, avoid voltage and electric radiation pollution; it can effectively prevent the oil temperature from being too high, and the cooling is good; greatly reduce the replacement rate of hydraulic oil.

The servo hydraulic system has better click and gear pump of the power system, which can reduce the noise of machine operation and production, and can better improve the working environment. The high-speed injection molding machine can save 60~70% of the total power compared with the ordinary injection molding machine, which greatly reduces the cost.

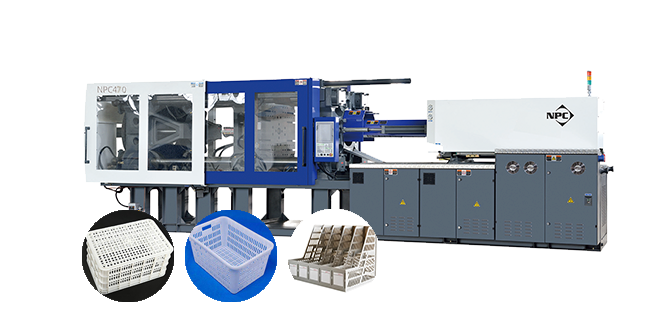

NPC Precision Machinery Co., Ltd is a manufacturer of precision plastic injection molding machine which combine professional R&D, manufacturing and after-sales services. NPC has more than 20 years of professional experience in the plastic machine industry and optimization of product structural design ,high-grade configuration, excellent performance and integrity services. If you are in need of high speed molding machine, please do not hesitate to contact us.