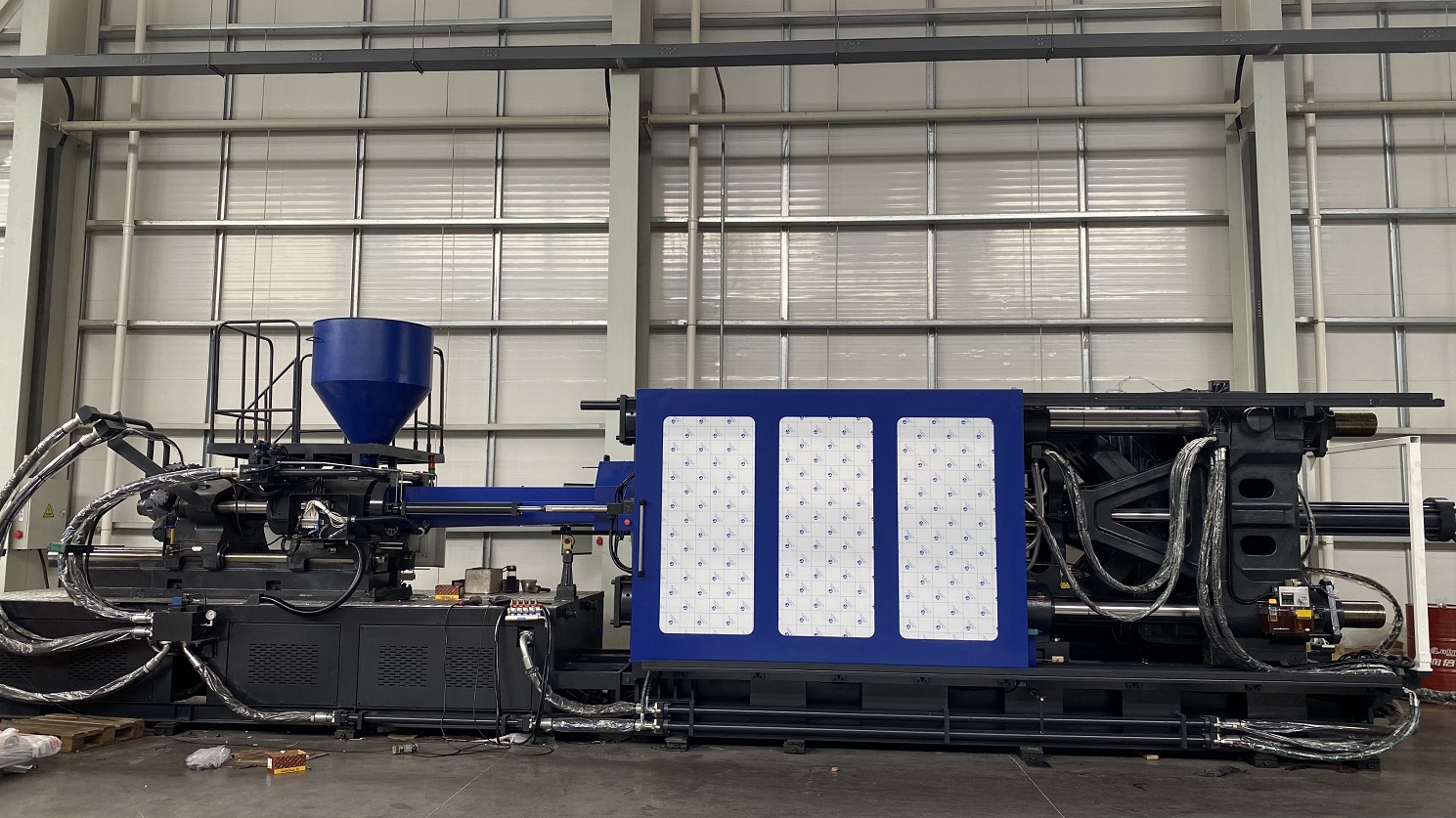

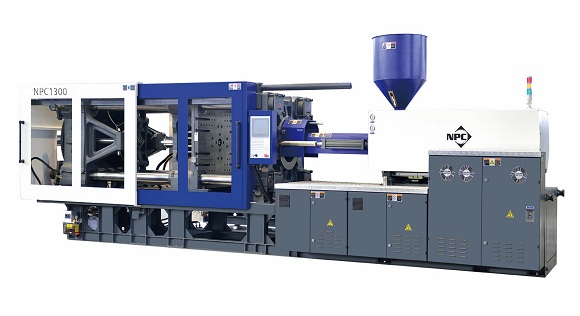

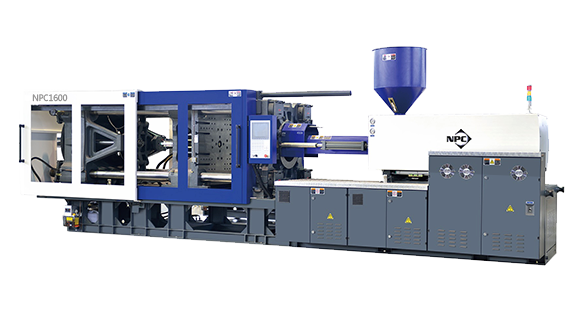

Servo 1000 Ton Injection Molding Machine NPC1000

Products introduction

high effiency,energy saving, high speed, stable,intelligent.high effiency,ene-rgy saving, high speed, stable,intelligent.high effiency,energy saving, high s-peed, stable,intelligent