Are you involved in a plastic manufacturing business or any business venture that produces plastic products? If Yes, then you need to have an injection molding machine as its use is significant for any plastic manufacturing technique.

In this article, I will enlighten you on the uses of an injection molding machine while discussing what an injection molding machine is all about that enables its use. Read along for a lovely read.

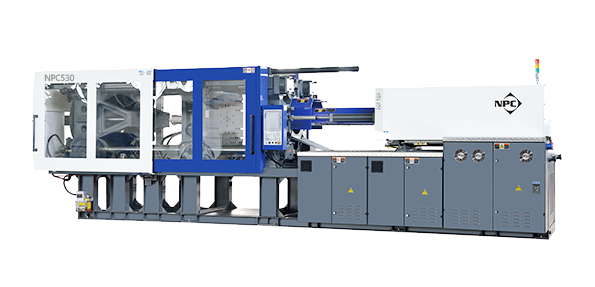

An injection molding machine is a machine that uses plastic custom-made molds to manufacture a wide range of identical copies of items and parts by working to the specifications.

The injection molding machine manufactures plastic products by injection molding process which involves a versatile manufacturing process that allows for the production of a wide range of different materials and finishes.

An injection molding machine consists of the following main parts; a material hopper, a rotating screw-type plunger or injection ram, a heating unit, a movable pattern, ejectors, and a mold inside a mold cavity. These components work together to ensure the functions and uses of the injection molding machine are adequately performed.

An injection molding machine is highly essential for any plastic or plastic products manufacturing process because of the following uses;

A variety of frequently used products, including simple plastic items like bottle tops as well as remote control casings, syringes, and more, are produced using an injection molding machine.

Additionally, injection molding machine is frequently utilized in the production of larger objects like automotive body panels. Numerous applications that call for recurring manufacturing procedures use injection molding machines.

The ability to scale up production to create a huge number of parts is the injection molding machine’s main reason for its essential usage. Injection molding is used to create parts from a variety of material types because it allows for the production of almost similar parts.

The cost of manufacturing and production is quite inexpensive once the upfront costs of the design and the molds have been paid for. As more parts are produced, production costs decrease.

Using injection molding machine lead to the generation of less waste than conventional manufacturing techniques like CNC machining, which removes excess materials. Therefore, an injection molding machine is often used to avoid using more production materials than necessary.

Are you in need of a reliable injection molding machine manufacturer or supplier?

As a reputable company with decades of expertise in the manufacture of the precision plastic injection molding machine, we are committed to supplying you with top-notch cost-effective injection molding machines for your plastic manufacturing business.

Kindly click here to reach out directly to us for an order or for more information about our products and services.