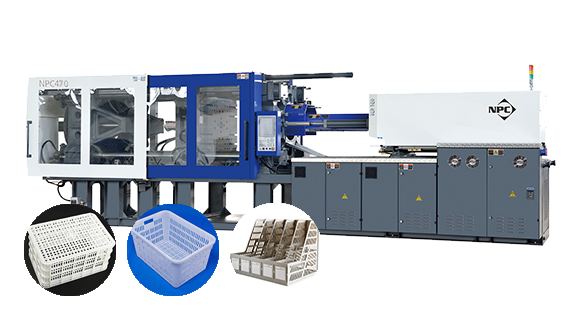

One of the most popular techniques for making similar plastic objects in large quantities is injection molding.

To successfully produce cost-effective, high-quality parts, as with any process, it is crucial to comprehend the precise design constraints that must be followed to enable the benefits that are immediately apparent.

To assist, we have succinctly outlined the benefits and drawbacks to take into account.

Injection molding can crank out a staggering number of pieces per hour. Speed might range from 15 to 120 seconds per cycle depending on the complexity and size of the mold.

Plastic injection molding is an automated process that is controlled and managed by a single operator, with machines and robotics handling the majority of the work. Automation lowers manufacturing costs since there are fewer overhead expenses.

Very high pressure is applied to the molds themselves. Because of the increased pressure on the plastic inside the molds, elaborate or complex shapes can be produced as well as parts with a lot of detail imprinted on them.

Before the tooling needs to be serviced, thousands of pieces can be manufactured.

There is a wide range of polymer resins available. The usage of multiple plastic materials at once is also possible; TPE, for instance, can be over-molded onto PP pieces.

Injection The second part you manufacture will be similar to the first one because the molding is a repeatable operation, etc. When trying to make high tolerances and reliable parts in large volumes, this is a significant advantage.

Fillers may be used in the molding material during the plastic injection molding process. These fillers can assist increase the strength of the finished product by reducing the density of the plastic while it is being molded.

Because of the necessary design, testing, and tooling, upfront expenditures are significant. Following the original design and prototyping (often using CNC or 3D printing), a prototype mold tool is created to mass produce the part. Finally, only following thorough testing throughout both steps, a part can be injection molded.

Plastic components must be built with injection molding in mind and adhere to the fundamental injection molding guidelines.

The setup process can take a while because of the complexity of the tooling and the need to empty the machine before producing the following item. Because of this, it has always been believed that injection molding is too expensive for short runs of parts.

The process of injection molding is fantastic! There is a wide variety of colors and materials, and it isn't "abs like" that we get with 3D printing; it is the actual thing.

Get in touch with us for further details and to order your molding machine.