High Speed 530 Ton Basket Injection Molding Machine NPC530

Products introduction

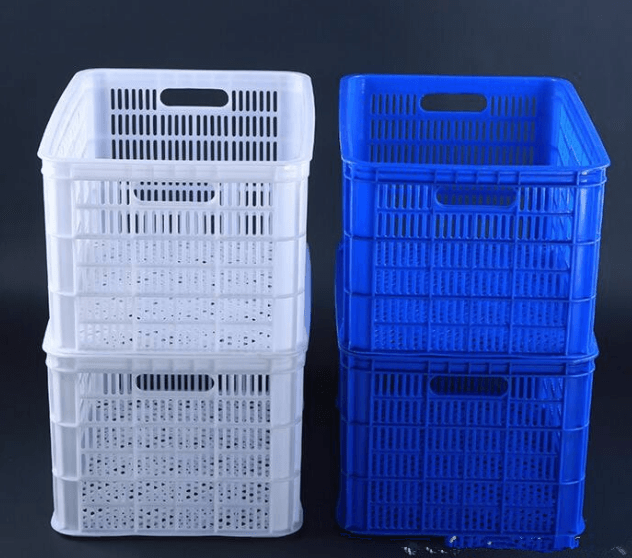

Basket high-speed series Injection Molding Machine(470T-530T) Large injection weight, Bimetalic screw and barrel, high speed capacity

Complete machine structure special design for the plastic fruits/vegetable baskets & crates high speed production;

Suitable for the high production capacity request of the plastic crates ,plastic baskets factory;

|

Specification |

|

NPC 530 |

|||

|---|---|---|---|---|---|

|

|

|

A |

|||

|

INJECTION UNIT |

|

|

|

|

|

|

Screw diameter |

mm |

100 | |||

|

Screw L/D ratio |

L/D |

17.1 |

|||

|

Shot volume(theoretical)(ps) |

cm³ |

3456 |

|||

|

Injection weight(ps) |

g |

3145 |

|||

|

Injection pressure |

Mpa |

126 |

|||

|

Screw speed |

rpm |

152 |

|||

|

CLAMPING UNIT |

|

|

|

|

|

|

Clamping force |

KN |

5300 |

|||

|

Open stroke |

mm |

910 |

|||

|

Space between tie bars(W*H) |

mm |

870*870 |

|||

|

Max.Mould height |

mm |

900 |

|||

|

Min.Mould height |

mm |

350 |

|||

|

Ejector stroke |

mm |

250 |

|||

|

Ejector force |

KN |

150 |

|||

|

Others |

|

|

|

|

|

|

Max.pump pressure |

Mpa |

17.5 |

|||

|

Motor power/servo power |

KW |

68.5 | |||

|

Heating power |

KW |

51.55 | |||

|

21.2Machine dimension(L*W*H) |

m |

8.53*2.08*2.80 |

|||

|

Oiltank cubage |

L |

890 |

|||

|

Machine weight |

t |

21 |

|||

By continuing to use the site you agree to our privacy policy Terms and Conditions.